Mechanical Process Piping

Fabrication and Installation

- Frank Millard & Co. Pipefitters have abundant knowledge and ability to layout, fabricate, assemble, install, maintain and repair piping systems that transport all types of fluids, slurries, and gasses in the Industrial sector.

- Frank Millard & Co. specializes in the installation of low and high-pressure steam systems including, but not limited to, process piping and boilers.

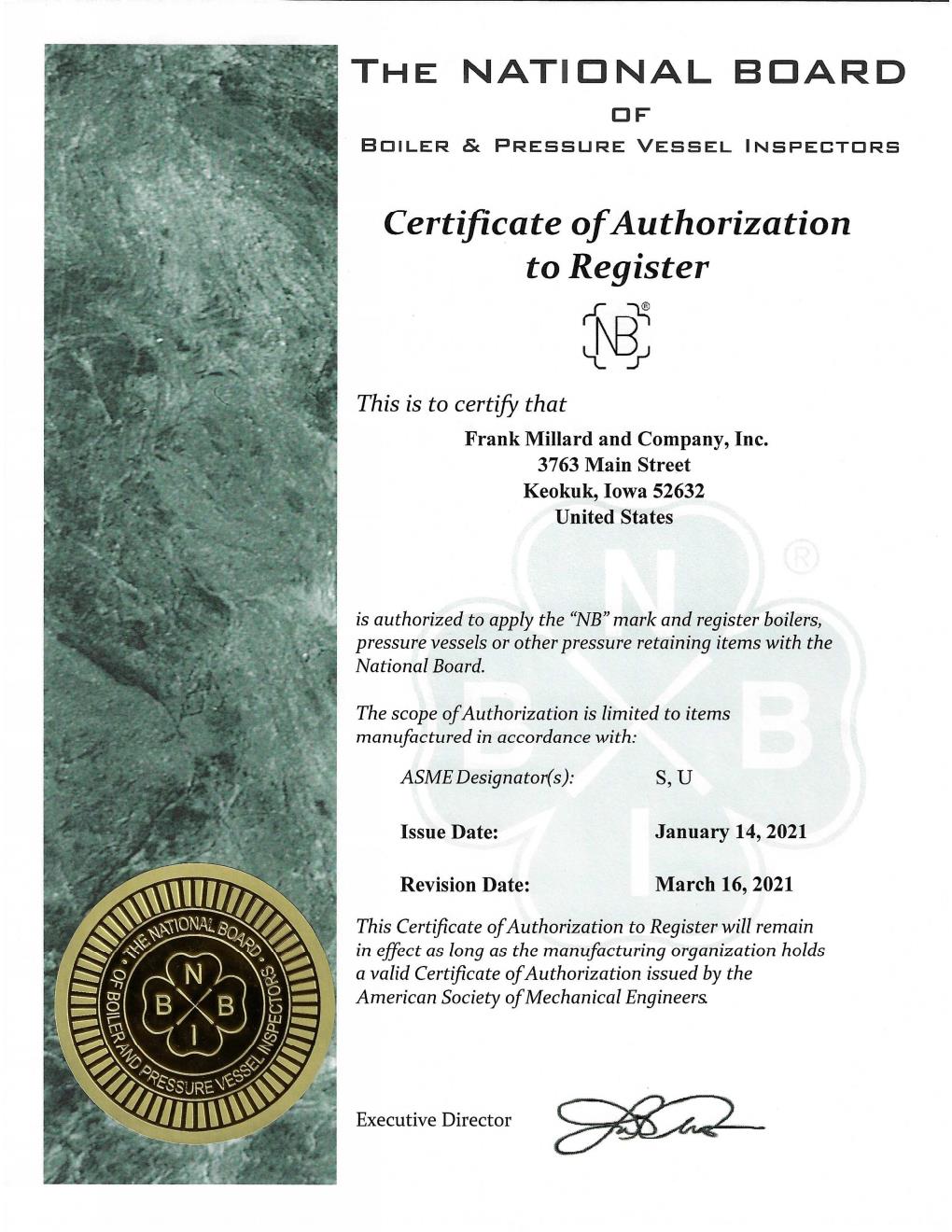

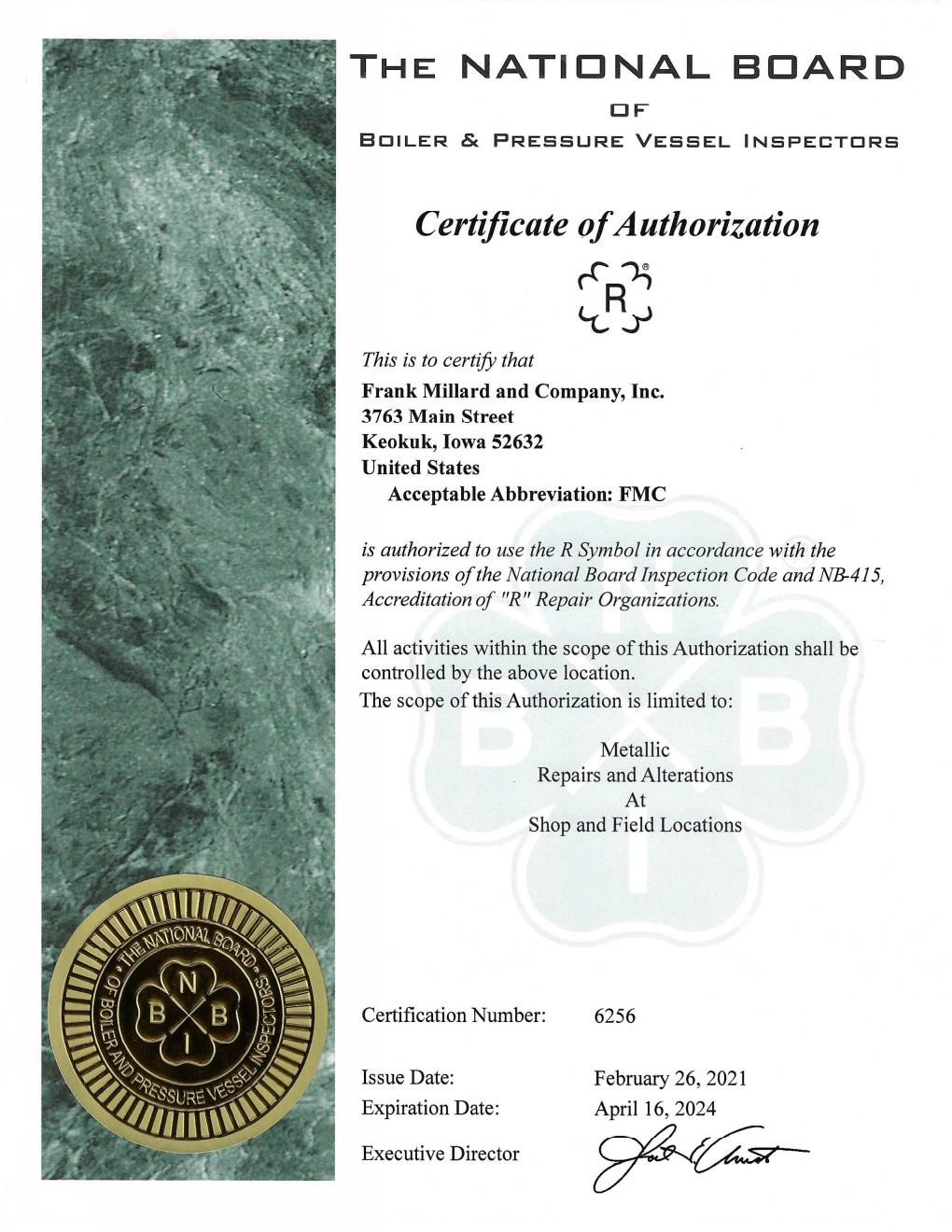

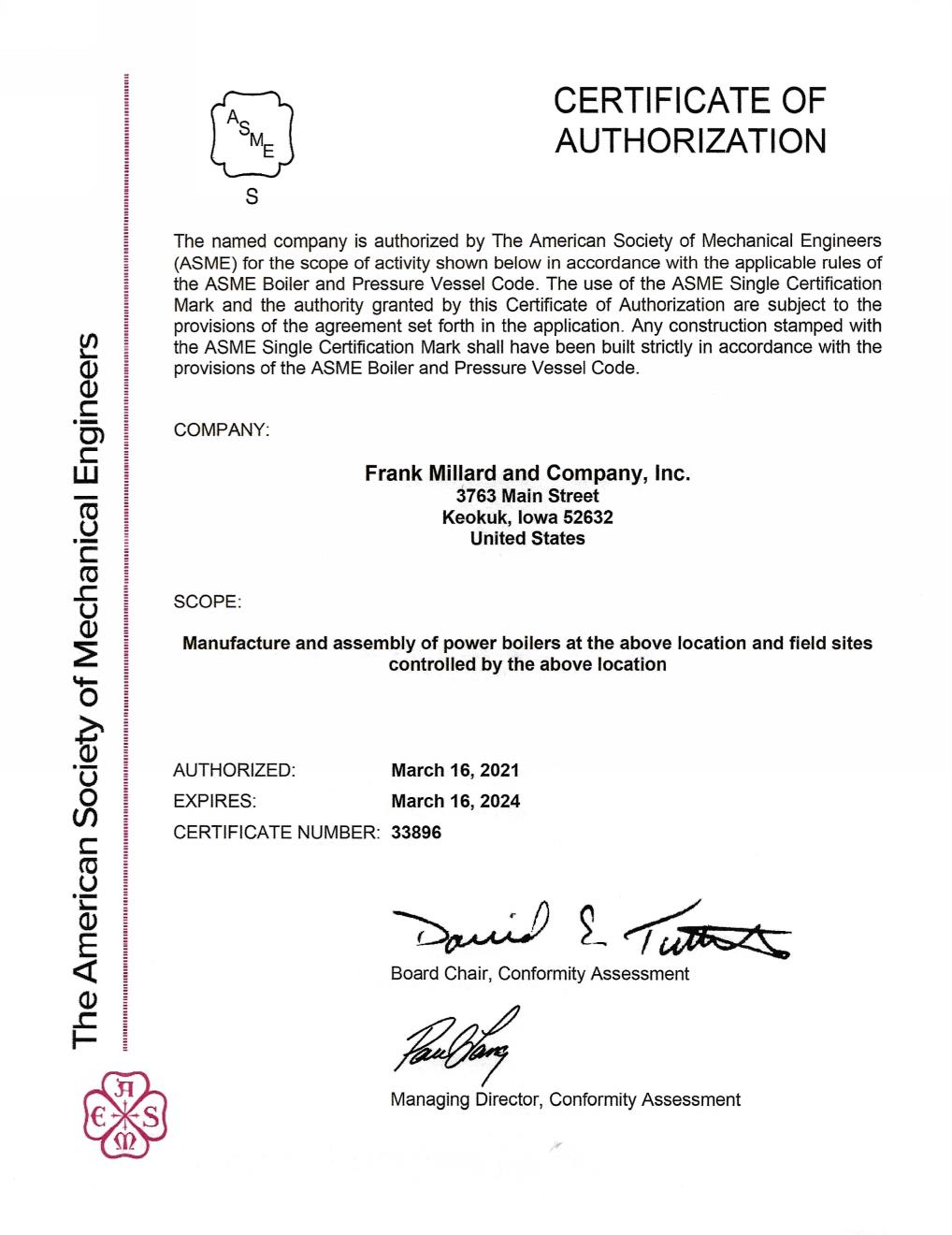

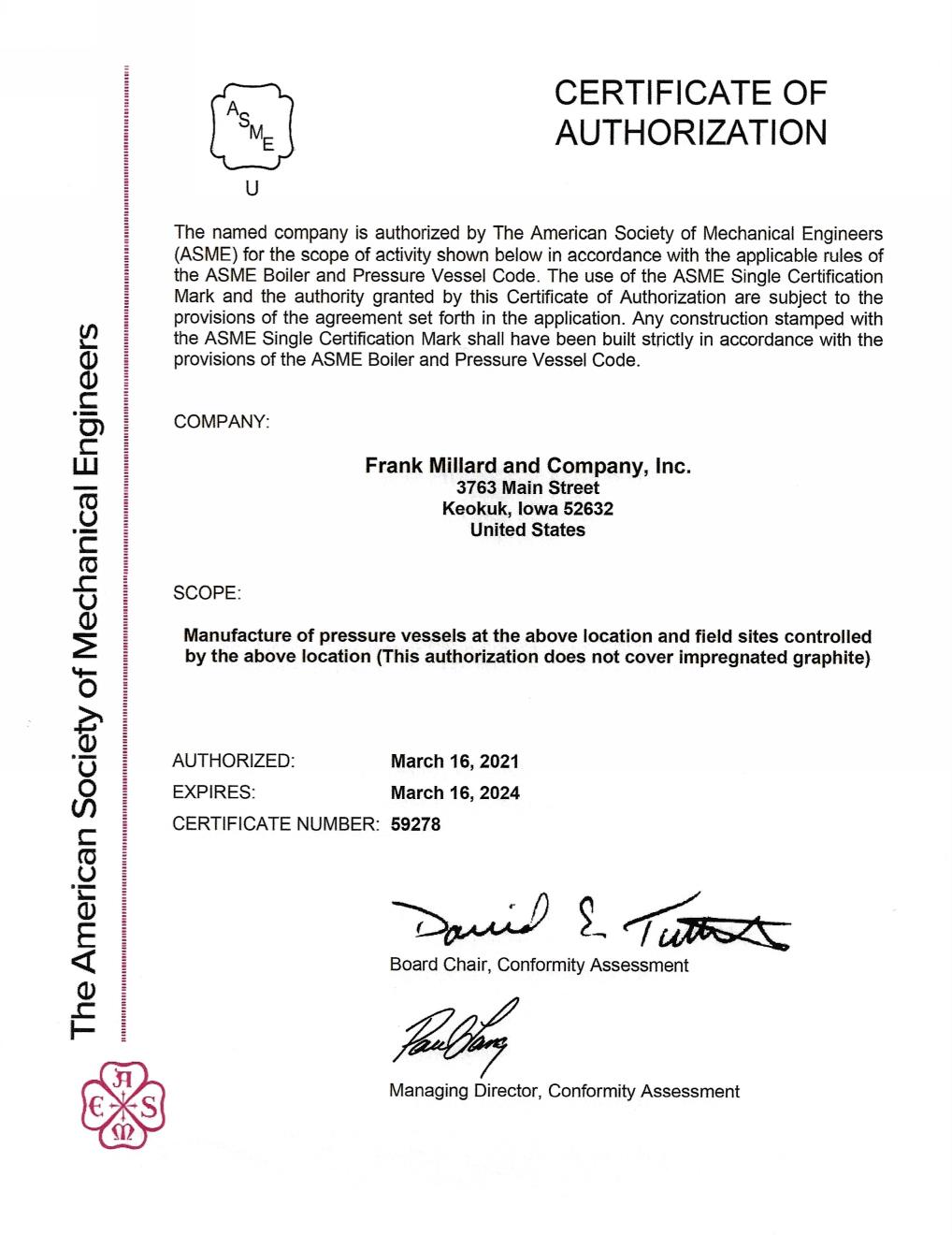

- Frank Millard’s Pipefitters possess “NB”, “U”, “R” and “S” Certifications to assemble, repair, or perform alteration of boilers and pressure vessels.

- Certified in air piping, with extensive experience in food grade and health care projects. Millard Pipefitters are highly sought after to tackle medical and food grade installations along with Powerhouse projects.

- Millard Co. Welders are certified in MIG, TIG and Stick welding for installation, maintenance and repair of all types of piping systems, as well as structural steel brackets and supports for such systems.

Millard Pre-Fabrication Shop Benefits

- Modern 40,000 SF Fabrication Facility

- Automated Shop Fabrication Equipment to increase Labor Efficiency

- UA Trained Work Force

- UA National Shop Agreement

- “NB”, “U”, “R” and “S” Stamps in Place

- QA/QC System in Place

- In-House Design and Detailing for Fabrication and Installation

- Fabrication Shop Centrally Located in the USA with access to major highways

- Ability to Send Shop Personnel to job site for field measurement verification as needed

Watts W-364 Pipe Cutting Machine

- W-364 Computer controlled pipe cutting machine conveys and rotates pipe from 3″ to 36″ OD with a 25′ machine bed capable of supporting 500 lbs. per foot for a maximum of 12,500 lbs.

- 6-axis profiling carriage on precision machined and hardened track. Simultaneous motion maintains the torch cutting position along the linear axis of the pipe and perpendicular to the linear axis to perform beveled holes and end cuts.

- The 3rd and 4th Axis of motion allows the oxy-fuel torch to rotate along the linear axis of the pipe and perpendicular to the linear axis to perform true beveled holes and end cuts. The maximum rotation angle allows the torch to rotate 45 degrees from vertical in both directions. This will allow the operator to create a fitting with the edge preparation done and ready to weld.

- Tracking torch head includes vertical and horizontal tracking mechanism to maintain torch height and pipe centerline to automatically compensation for bent or out-of-round pipe.

- Floating pipe clamp with locking mechanism for accurate rotation that eliminates pipe walk.

- Hydraulic controlled lift deck with powered machine conveyor.

- Hydraulically actuated off loader arms to transfer the pipe off the cutting cell.

- PypeServer™ software for at-machine and remote pipe cut programming and job management. This software simplifies the importing, design and nesting of parts, streamlines job estimating, scheduling and inventory management, and allows job tracking in real-time.