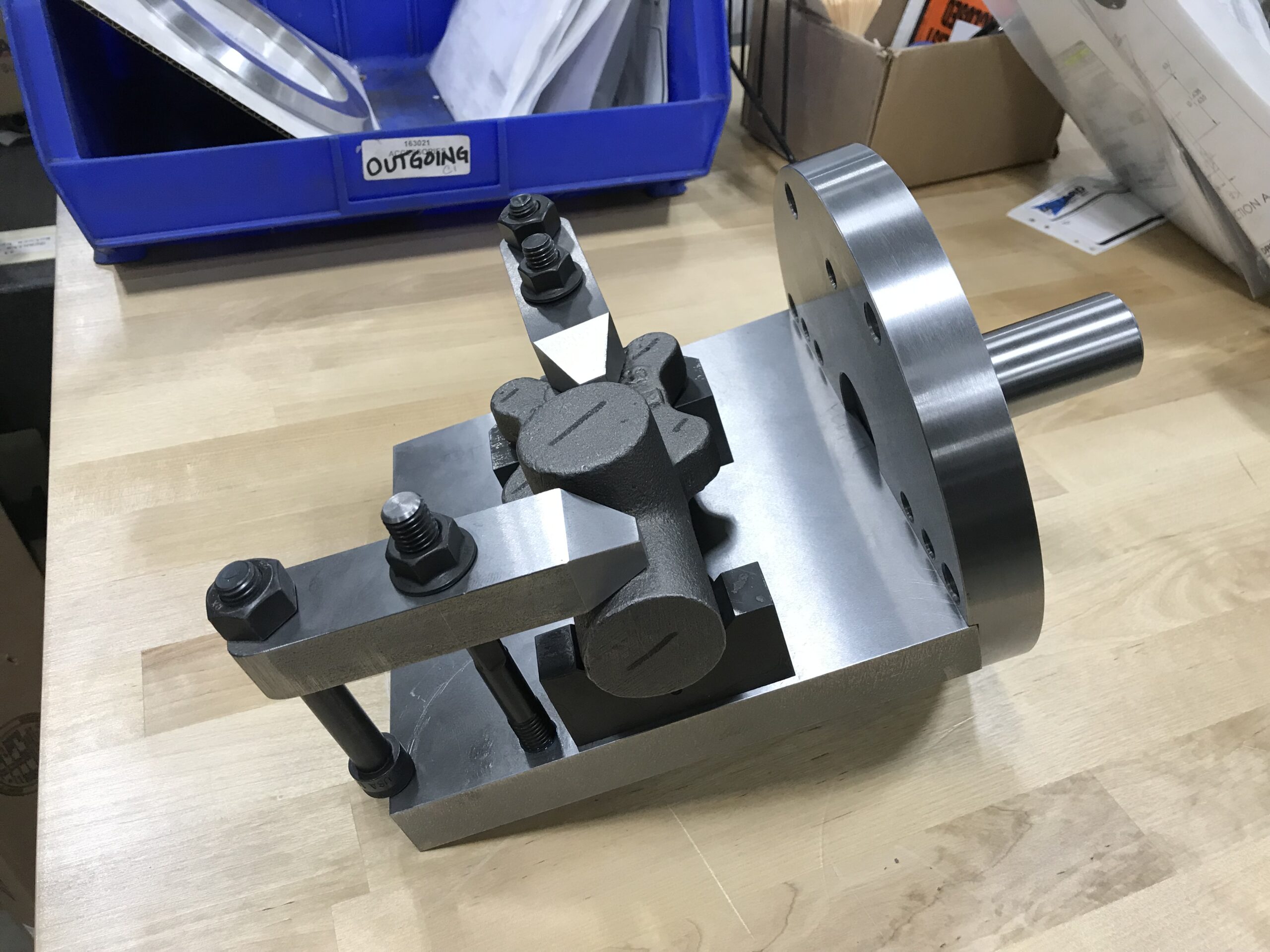

Precision Machining

Complete Machining Services

- CNC and Manual Milling

- CNC and Manual Turning

- Drilling

- On-Site Heat Treating / Annealing Capabilities

- Precision Grinding For Plate and Round Stock

- Tool Sharpening

- All Type of Metals from Low Carbon Steels to 300/400 Series Stainless Steel and High Yield Alloys

- Simple to Complex Machining Solutions

- Fixture Design and Manufacturing

- Shop Production Cell Layout is set up for anything from “One-Off” projects to Job Shop Production

Simple 4 Step Process

- Proposal

Our proposal will be quickly developed from the assessment of your Detailed Drawing or 3D Model, Inspection of the Part, the Quality Control / Testing Required and the Delivery Requirements. - Scheduling

Utilizing our CRM Platform, we can immediately enter your project into our scheduling system to efficiently plan our machinist and equipment availability that meets your scheduling needs. - Manufacturing

Whether your project is manufactured on our State-of-the-Art Okuma CNC Mill or Lathe, or in our Specialized Manual Machining Cells, our Experienced and Highly Trained Journeyman Machinists will Complete Your Project On Time and with the Exacting Quality Control Standards Required. - Value Added Services

In Addition to our Complete Machining Services, we also offer Value Added Services such as Drafting and Design Services utilizing Autodesk Inventor, Revit and AutoCAD, as well as On Site Heat Treating, Abrasive Blasting and Weldments of All Types.

Highly Skilled Journeyman Machinists with over 25 Years Experience!

A Division of the Frank Millard & Company Fabrication Facility. Modern 40,000 SF Production Facility which also offers complete Sheet Metal and Light Steel Fabrication, All Types of Mechanical/Process Pipe Fabrication, Machine Repair & Modification and Electrical & Control Cabinets. Shop includes complete shipping/receiving docks, overhead material handling equipment and state of the art manufacturing equipment with Autodesk Inventor, Inventor CAM, HSMWorks, AutoCAD and Revit capabilities.

Key Shop Equipment

- Turning Capabilities

Okuma GENOS L300E-M-e CNC Lathe: 15” Swing with 40” Length

Okuma LB4000 EXII SpaceTurn CNC Lathe: 20” Swing with 40” Length

Monarch Toolmaker’s Lathe: 20” Swing with 144” Length

Monarch Toolmaker’s Lathe: 26” Swing with 72” Length

Monarch Toolmaker’s Lathe: 20” Swing with 54” Length

Monarch Toolmaker’s Lathe: 15” Swing with 30” Length - Milling Capabilities

Okuma GENOS M560V CNC Mill: X-Axis 40”, Y-Axis 18”, Z-Axis 22”

Twinhorn VQ-1600 CNC Mill: X-Axis 62”, Y-Axis 28”, Z-Axis 26”

DeVlieg Spiromatic Horizonal Boring and Milling Machine: 30” x 40” Table with 3” Spindle

SAJO Mill: 16” x 53” Table

(2) Bridgeports: 9” x 48” Table - Sawing Capabilities

DoAll Horizontal Bandsaw: 13” Throat Diameter

DoAll Vertical Bandsaw: 12” Throat Diameter - Grinding Capabilities

Chevalier Inside/Outside Diameter Grinder: 1” ID and 6” OD Capabilities

Brown and Sharp Surface Grinder: 8” x 18” Surface Plate - On-Site Heat Treat Capabilities

Lucifer Heat Treat and Annealing Oven: 2,000 Deg – 24”x24”x24” Box

Cress Heat Treat and Annealing Oven: 2,000 Deg – 12”x12”x17” Box

Cress Heat Treat and Annealing Oven: 2,000 Deg – 12”x12”x20” Box